The Rising Demand for Quality Ice in the Beverage Industry

In today‘s dynamic beverage market, consumer expectations extend beyond just the drink itself to encompass the entire experience. A critical, yet often overlooked, component is the ice. For cafes, bubble tea shops, juice bars, and quick-service restaurants, the quality of ice directly impacts drink taste, presentation, and customer satisfaction. Cloudy, fast-melting, or oddly-shaped ice can dilute beverages prematurely and detract from their visual appeal.

This is where a dedicated large cube ice maker production line becomes a strategic investment. Moving beyond small-scale, on-demand ice makers, these industrial systems are engineered for the consistent, high-volume output of premium, food-grade ice specifically formed into convenient cups or molds. They offer unparalleled efficiency, hygiene, and consistency, empowering businesses to build a superior brand reputation and streamline their ice cube making business operations.

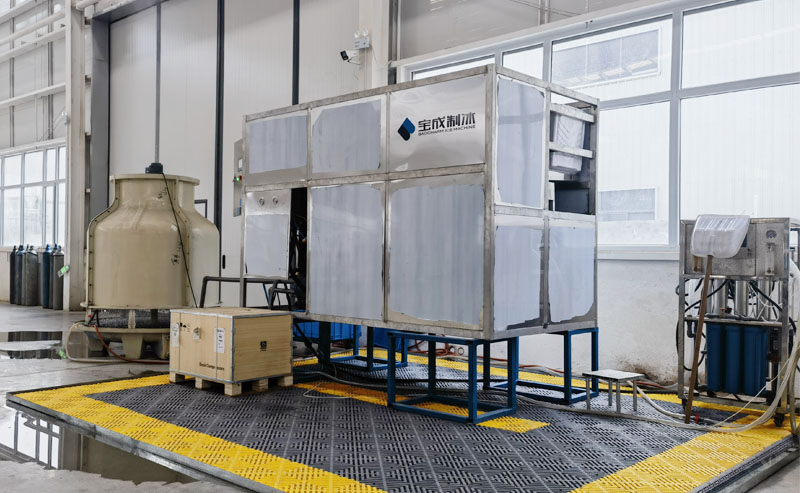

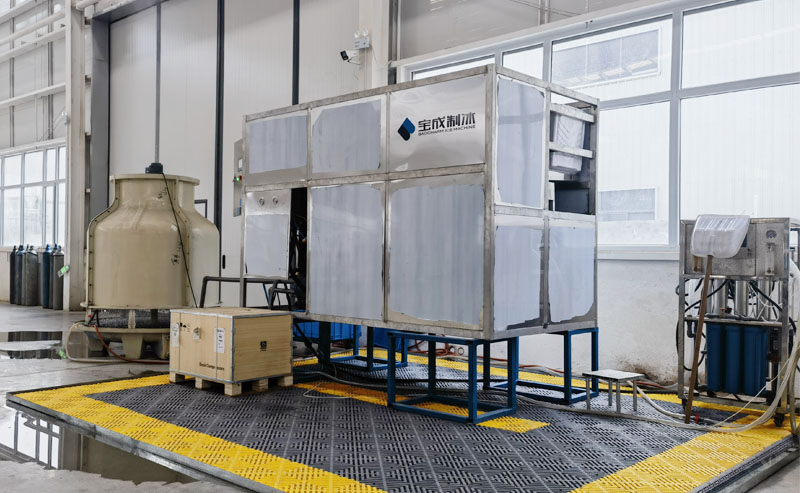

Core Equipment: An Overview of the Industrial Ice Production Line

An industrial ice cube making machine within a full production line represents a significant technological leap from standard commercial ice makers. While a typical countertop or underscounter unit produces ice for immediate use, a full ice cube making plant is an integrated, automated system designed for continuous production, processing, and packaging.

Key Components of a Full Production Line

- Large Cube Ice Maker: The heart of the system. These machines use advanced refrigeration cycles and often a slow-freeze process to create crystal-clear, dense, slow-melting large cube ice. They are built for durability and high daily output.

- Ice Storage Silo/Bin: A sanitary, insulated hopper that stores the produced ice, often with automated level sensors to regulate production cycles.

- Conveying & Handling System: A network of food-grade stainless steel conveyors and elevators that transport ice from the maker to processing stations without contamination.

- Optimization & Drying Unit: This may include crushers (for nugget ice), sorters, and air-knife systems to remove excess surface moisture, ensuring dry, free-flowing ice.

- Edible Ice Cup Production Line: The specialized downstream module. This automated system precisely fills pre-formed edible or PLA cups with the optimized ice, seals them, and prepares them for packaging.

- Automated Control Panel: The brain of the operation, allowing for centralized monitoring and control of temperatures, cycle times, and production flow.

Specialized Design for Edible Ice Cups

Production lines for edible ice cup production line applications incorporate stringent hygiene standards. Materials in contact with ice are NSF-certified stainless steel or food-grade plastics. The environment is often designed to minimize airborne contaminants, and the packaging process is fully enclosed to ensure the final product is safe for direct consumption.

The Production Journey: From Water to Premium Ice Cup

The transformation of raw water into a sealed, ready-to-sell ice cup is a meticulously controlled process:

- Water Pretreatment: The foundation of quality ice. Source water undergoes multi-stage filtration (sediment, carbon) and often reverse osmosis (RO) or deionization. This removes minerals, impurities, and odors, resulting in the clarity, taste neutrality, and hardness required for perfect, bubble-free ice.

- Ice Formation (Large Cube Generation): Pre-treated water is circulated into freezing chambers or molds within the large cube ice maker. Advanced systems use a directional freezing technique, where water freezes from one direction to push impurities and air bubbles out, yielding exceptionally clear and hard ice blocks or large cubes.

- Harvesting & Post-Processing: The formed ice is released (harvested) through a warm gas defrost cycle. It is then conveyed to a crusher/sizer (if producing nugget ice) or a breaker (for cube ice) and through a drying tunnel.

- Quality Inspection & Packaging: Optical sensors or manual checkpoints may verify ice clarity and size consistency. The ice is then automatically dispensed into cups, which are lidded, sealed, coded, and packed into cartons or crates for cold storage or distribution.

Key Technologies & Quality Control: The Pillars of Excellence

Several advanced technologies ensure the reliability and output quality of a modern production line:

- High-Efficiency Refrigeration Technology: Utilizes eco-friendly refrigerants and optimized heat exchanger designs (like falling film evaporators) to maximize ice production per kilowatt-hour, significantly lowering the operational cost of the ice cube making business.

- Precision Temperature & Process Control: Sophisticated PLC (Programmable Logic Controller) systems maintain exact temperatures throughout freezing, storage, and processing. This ensures consistent ice density and morphology batch after batch.

- Comprehensive Automation: From auto-filling water to automated harvesting, conveying, filling, and packaging, minimal manual intervention reduces labor costs and the risk of contamination.

- Sanitation & Hygiene Assurance: Built-in Clean-in-Place (CIP) capabilities, antimicrobial surface coatings, and the use of easy-clean materials are critical. Regular microbial testing protocols for both water and finished ice are part of a robust quality management system, essential for any edible ice operation.

Market Advantages & Applications of Beverage Ice Cups

Investing in a dedicated production line offers compelling advantages for beverage businesses and dedicated ice suppliers:

- Superior Product Consistency: Delivers uniform, high-clarity ice that enhances beverage aesthetics and melting performance.

- Brand Differentiation: Customizable cup logos or unique ice shapes (large cubes, nuggets) create a memorable brand experience.

- Operational Efficiency: Eliminates the labor, waste, and inconsistency of manual ice scooping or bagging. Provides a steady, reliable ice supply.

- Enhanced Hygiene: A fully automated, closed process drastically reduces contamination risks compared to open ice bins.

- Scalability: Industrial ice cube making machine lines can be designed to scale from mid-volume outputs to full-scale plant capacities, supporting business growth and wholesale opportunities.

The market for premium, conveniently packaged ice is expanding rapidly, driven by the global growth of out-of-home beverage consumption and heightened food safety awareness.

Navigating Operational Challenges & Solutions

Establishing and running an ice cube making plant comes with considerations. Proactive planning addresses these effectively:

High Initial Investment

- Solution: A detailed ROI analysis factoring in labor savings, reduced waste, and premium product pricing. Modular systems allow for phased expansion. Government grants for energy-efficient industrial equipment may be available.

Water & Energy Consumption

- Solution: Integrating water recirculation systems and high-efficiency, ENERGY STAR-rated compressors and pumps. Utilizing ice production during off-peak electricity hours can also reduce costs.

Maintenance & Technical Expertise

- Solution: Partnering with a supplier (like BAOCHARM) that offers comprehensive after-sales support, readily available spare parts, and operator training programs ensures long-term reliability and uptime.

Meeting Food Safety Regulations

- Solution: Selecting equipment with relevant certifications (NSF, CE) and designing the facility with hygienic zoning. Implementing a documented HACCP (Hazard Analysis Critical Control Point) plan is crucial for edible ice production.

Conclusion & Your Next Step

A large cube ice maker production line is more than just machinery; it‘s a transformation tool for businesses serious about quality, efficiency, and growth in the competitive beverage space. It provides the foundation to build a reputable and profitable ice cube making business, ensuring every drink served is accompanied by ice that meets the highest standards of clarity, purity, and performance.

Ready to explore how a tailored ice production solution can elevate your operation?

At BAOCHARM, we specialize in designing and supplying turnkey industrial ice solutions—from standalone large cube ice makers to complete automated edible ice cup production lines. Our expertise helps you navigate the technical and business decisions to find the optimal system for your output goals and budget.

Contact our expert engineering and sales team today for a free, no-obligation consultation. Let’s discuss your project requirements and craft a solution that fuels your success.

December 17, 2025

December 17, 2025